WHAT WE DO?

Our services

Machinery

Advanced technology

We have the equipment that your company needs. Our different processes allow the manufacture of any type of elements that are difficult to replace or in continuous operation, with high downtime costs and / or unavailability.

Reliability, maintainability & availability

Our policy is focused on the constant maintenance and renewal of machinery, always with state-of-the-art technology and up-to-date with innovations in the industrial market, to ensure the highest standards in quality of the final product.

.

Learn about the wide variety of processes we have and the machinery at your disposal:

Bending Area

CNC

4 Trumpf 7036 6 axis

3 LVD HPS 6 axis

1 Shlejia YQ28 4 axis

Conventional

8 Press Brake (Chicago / Verson / Newton)

.

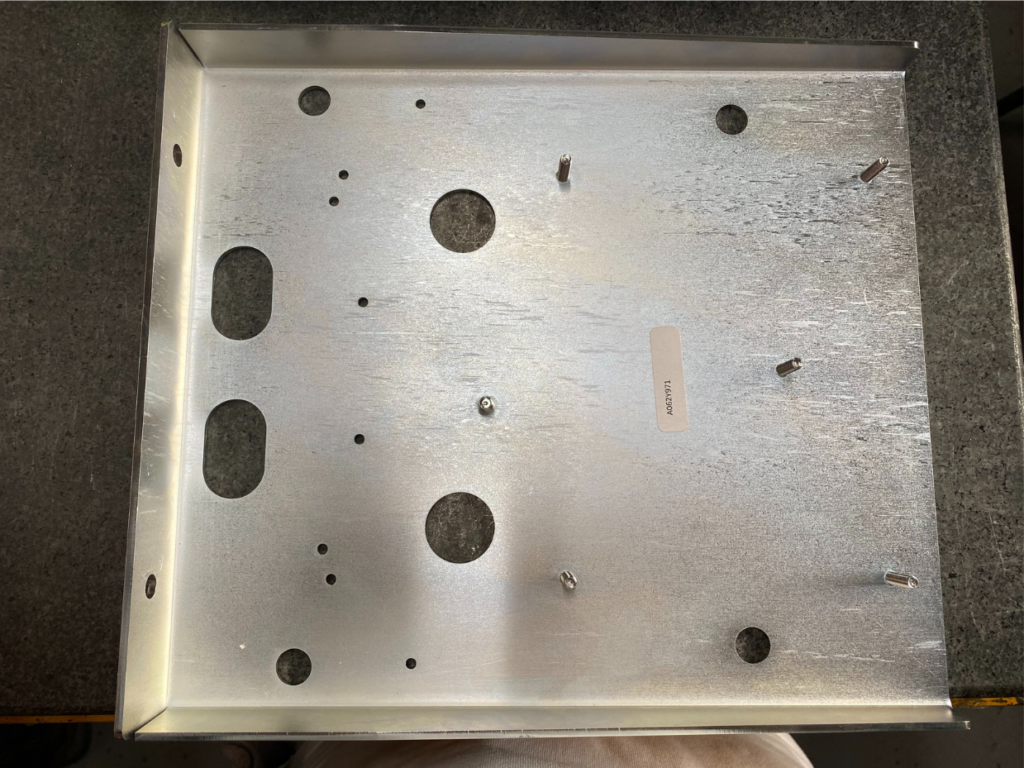

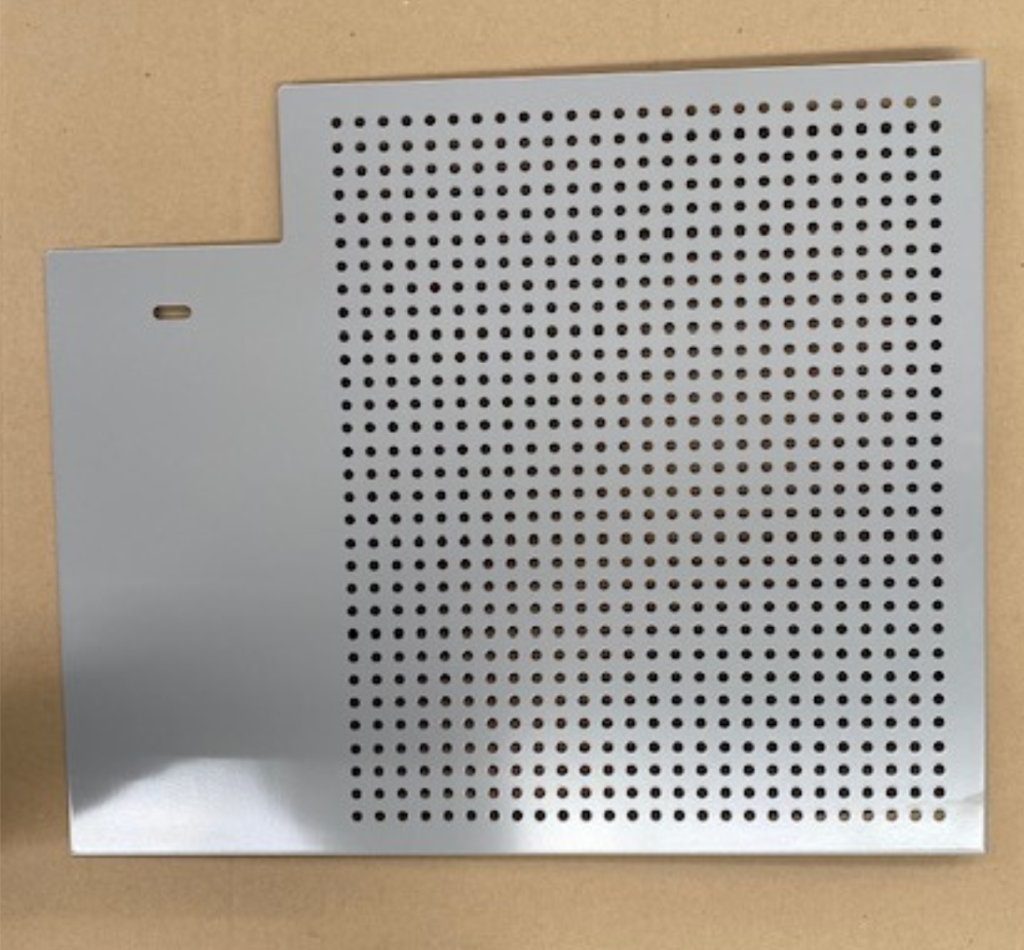

Laser Cut & Punching

5 Trumpf Lasers bed 5 ft X 10 ft:

2 TruLaser 1030 CO2

1 TruLaser 1030 Fiber

1 TruLaser 2030 Fiber

1 TruLaser 3030 CO2

3 CNC Punch:

1 Amada Pega

1 Amada Octo

1 Amada V

.

Stamping Area

Progresive Press

10 Press lines (from 500 to 110 Ton) equipped with

decoiler – straightener –

Feeder -press

Manual Press

20 Presses (from 250 to 110 Ton) Manual Feeding

3 Presses (60-30 Ton) Manual Feeding

2 Deep drawing presses (double effect)

.

Painting Line

Powder Coating Line

5 steps clean tunnel

GEMA powder cabin with optional automatization 90ft cured tunnel.

.

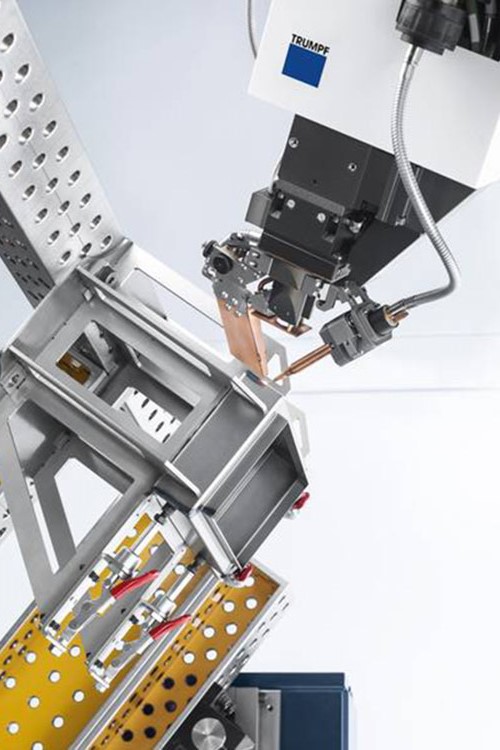

Machining & Welding Area

Welding

TruLaser Weld 5000 (Kuka Robot)

MIG

TIG

Spot Welding

Machining

Hass Lathe ST20

Vertical Mill VM2

Vertical Mill VF3

Vertical Mill Hitachi Seiki

EDM Baoma

Surface grinder

Drill

.